Welding is a process that joins metal pieces together using heat or pressure. It creates strong, permanent bonds that hold structures and products intact. This technique has become essential in countless industries around the world today.

From building bridges to manufacturing cars, welding plays a critical role everywhere. Without it, modern construction and production would simply grind to a halt. Research suggests that welding supports millions of jobs and drives economic growth globally. In this article, we'll explore the evolution of welding in detail. Read on!

The Evolution of Welding and Its Modern Impact

Welding has traveled a long road since its humble beginnings centuries ago. Early blacksmiths used forge welding, hammering heated metals together to create basic tools. As many know, this required incredible skill and physical strength to achieve results. The process was slow, labor-intensive, and limited in what it could produce effectively.

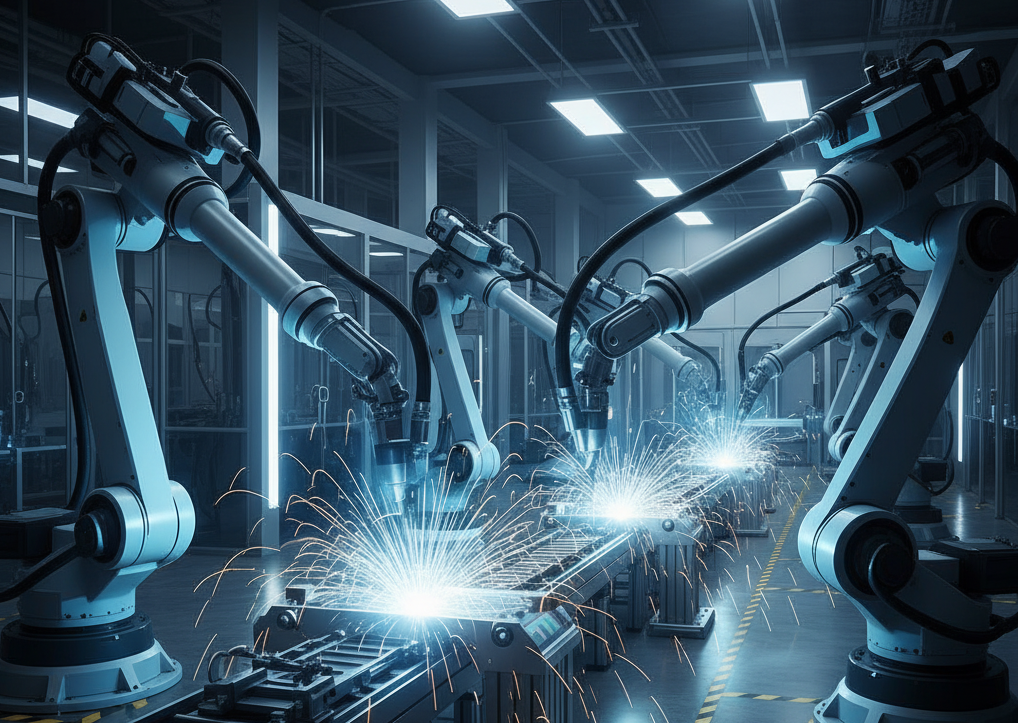

Today's welding technology would astonish those early craftsmen beyond belief, without a doubt. Modern welders use automated systems, laser technology, and computer-controlled precision for complex tasks. These advancements have made welding safer, cleaner, and far more efficient than ever.

Historical Evolution (From Origins to Early 20th Century)

Prehistoric & Ancient Welding (Bronze Age to Middle Ages)

Welding began long before electricity or modern tools existed. Early humans joined metals by heating and hammering them together. Around 3000 BCE, during the Bronze Age, artisans fused small pieces of gold using heat and pressure. These methods were crude but effective for jewelry and simple tools. Blacksmiths in ancient Egypt and Mesopotamia refined the process using charcoal forges. They could reach high enough temperatures to soften metals like copper and iron. By the Iron Age, welders shaped weapons and armor through repeated heating and hammering. This technique, known as forge welding, laid the foundation for future metalwork.

Interestingly, many believe the famous Iron Pillar of Delhi—built around 400 CE—showcases ancient welding skill. Though it’s made of wrought iron, it shows almost no corrosion after centuries. Experts think early Indian metalworkers mastered joining iron without modern fluxes. Throughout the Middle Ages, blacksmiths across Europe and Asia kept improving forge methods. They used bellows to raise furnace temperatures and created stronger joints. Without standardized techniques, each weld depended heavily on the smith’s experience. Still, these craftsmen gave it their all to build everything from horseshoes to cathedral gates. Their work may seem basic today, but it was groundbreaking then. From my point of view, their ingenuity paved the way for every welding innovation that followed.

Forge Welding in the Industrial Revolution

The Industrial Revolution brought massive changes to how people worked with metal. Factories needed stronger, faster ways to join iron and steel parts. Forge welding remained central but evolved alongside steam power and mass production. Blacksmiths now used mechanical hammers powered by water or steam, saving time and effort. Railroads, ships, and bridges demanded reliable metal joints on a huge scale. Because of this, workshops began training more welders in consistent forge techniques. Though still manual, the process became more systematic and repeatable.

According to experts, this era marked the shift from artisan craft to industrial skill. Workers no longer made single items—they produced hundreds of identical parts. Forge welding couldn’t keep up forever, though. As machines grew larger and materials stronger, heat-and-hammer methods hit their limits. Some joints simply couldn’t hold under industrial stress. Without the Industrial Revolution’s demands, that leap might have taken much longer. Clearly, this period was a turning point—not the end of forge welding, but the beginning of its replacement.

Birth of Electric Arc Welding (1880s–1920s)

Electric arc welding emerged when scientists began experimenting with electricity and metal. In the 1880s, Russian inventor Nikolay Benardos demonstrated the first practical arc process. He used a carbon electrode to create a sustained spark between metal pieces. Soon after, others improved the method by using metal electrodes that melted into the joint. This created a stronger, more reliable bond than forge welding ever could. By the early 1900s, arc welding started appearing in shipyards and factories.

World War I gave this technology a major boost. Armies needed fast, durable repairs for tanks, ships, and weapons. Traditional methods couldn’t meet wartime urgency or strength requirements. Arc welding, despite its complexity, offered a solution. Companies like Lincoln Electric and ESAB began producing commercial welding machines. Safety gear and training also improved, though conditions were still tough. From my point of view, this period was the true birth of modern welding. It shifted metal joining from fire and muscle to science and current. Without a doubt, the 1880s–1920s laid the electrical foundation for everything that followed.

Interwar Innovations & Standardization (1920s–1940s)

Between the world wars, welding moved from novelty to necessity. Engineers and manufacturers worked hard to refine electric arc methods. One big leap was the coated electrode, which protected molten metal from air. This made welds cleaner, stronger, and easier to control. Companies invested in research, and governments recognized welding’s strategic value. In fact, standards began appearing to ensure consistent quality across industries. The American Welding Society, founded in 1919, played a key role in this push.

By the late 1930s, new techniques like resistance welding and submerged arc welding emerged. These were perfect for auto plants and large-scale construction. When World War II hit, standardized welding became a wartime asset. Shipyards trained thousands of welders—including many women—to build vessels rapidly. Rosie the Riveter had her welding cousins, giving it their all on the home front. Because of earlier standardization, these workers could produce reliable joints quickly. According to experts, this era turned welding into a respected engineering discipline. It was no longer just a trade—it was a science with rules, codes, and real impact.

Post-War Boom & Solid-State Revolution (1950s–1980s)

After World War II, welding exploded in both industry and daily life. Factories built everything from cars to kitchen appliances using automated welding lines. The rise of MIG (metal inert gas) and TIG (tungsten inert gas) processes changed the game. These methods used shielding gases to protect welds, making them cleaner and more precise. Aerospace and automotive sectors adopted them quickly for high-quality joints. At the same time, stick welding remained popular for field repairs and construction.

The real breakthrough came with solid-state electronics in the 1970s and 80s. Transistors and circuit boards replaced bulky transformers in welding machines. This made equipment lighter, more efficient, and easier to control. Robot arms started welding car frames with unmatched speed and accuracy. Many people think this shift marked the move from manual skill to programmed precision. Interestingly, even small shops benefited from cheaper, more reliable machines.

Digital Age & Inverter Technology (1990s–2010s)

The 1990s brought a quiet revolution: inverter-based welding machines. Unlike old transformer models, inverters used digital circuits to control power precisely. This made welders smaller, lighter, and far more energy-efficient. A machine that once weighed 200 pounds now fit in a backpack. Hobbyists, farmers, and contractors all gained access to pro-level tools. Plus, digital displays let users fine-tune settings like never before.

At the same time, software began playing a role in welding quality. Pulse welding, synergic controls, and parameter memory became common features. These allowed even beginners to produce clean, consistent beads. Industries like shipbuilding and pipeline construction adopted advanced processes like FCAW and SAW with digital oversight. Without a doubt, the 1990s–2010s turned welding into a high-tech field. Machines didn’t replace welders—but they gave them superpowers.

Smart Welding in the 2020s

Today’s welding is smarter, safer, and more connected than ever. In the 2020s, “smart” welders come with Wi-Fi, sensors, and real-time analytics. They can detect joint gaps, adjust settings automatically, and log every weld for quality control. Some even use AI to suggest optimal parameters based on material and position. This isn’t science fiction—it’s on factory floors right now.

Training has also evolved. Augmented reality (AR) goggles let apprentices practice without striking an arc. Cloud platforms track welder performance across global teams. Interestingly, sustainability is driving innovation too—new methods reduce spatter, fumes, and energy use. From my point of view, modern welding balances human skill with machine intelligence. Many people think this synergy is the future: welders as tech-savvy problem solvers, not just torch holders. As research suggests, the next decade may bring fully adaptive robotic systems. But one thing stays the same—welding remains essential to building our world.

The Future of Modern Welding and What Lies Ahead

Welding is heading toward a future powered by intelligence, precision, and sustainability. Engineers are developing systems that learn from every weld they make. These smart machines can predict failures, optimize energy use, and guide human welders in real time. Portable hybrid systems now combine multiple processes in one lightweight unit, making fieldwork easier than ever. From my point of view, the line between human skill and machine support is blurring in the best way.

Interestingly, green technology is also reshaping the industry. New methods aim to cut emissions, reduce waste, and conserve power. Research suggests that by 2030, many workshops will run on clean-energy welders. Augmented reality and remote collaboration tools are helping train the next generation faster. Without a doubt, the future isn’t about replacing welders—it’s about empowering them. The craft remains central, but the tools around it keep getting smarter every year.

Frequently Asked Questions

What is the most common welding method used today?

MIG (Metal Inert Gas) welding is the most widely used method today. It’s fast, versatile, and works well on steel, aluminum, and other metals. Beginners and professionals alike favor it for clean, strong joints. Because it uses a wire feed and shielding gas, results are consistent. Many auto shops and fabrication shops rely on MIG daily.

Is welding still a good career in 2025?

Yes, welding remains a strong career choice in 2025. Skilled welders are in high demand across construction, manufacturing, and energy sectors. With new tech, welders now earn more and work safer. Training programs are shorter than many college degrees. Many experts say welding offers job stability and room to grow.

How has technology changed welding over the last 20 years?

Technology has made welding more precise, efficient, and accessible. Inverters replaced bulky transformers, and digital controls improved accuracy. Robotics now handles repetitive tasks in factories. Smart welders store settings, monitor performance, and even connect to apps. These tools help both pros and hobbyists achieve better results with less effort.

Can welding be done without gas?

Yes, welding can be done without gas using flux-core wire or stick electrodes. These methods create their own shielding through chemical coatings. They’re ideal for outdoor or windy conditions where gas would blow away. Many field welders prefer them for repairs and construction. However, gas-shielded welds are usually cleaner and smoother.

What’s the difference between TIG and MIG welding?

TIG uses a non-consumable tungsten electrode and separate filler rod. MIG feeds a continuous wire that melts into the joint. TIG gives more control and cleaner finishes but is slower. MIG is faster and easier for long seams or thick metal. Choose TIG for precision; choose MIG for speed and simplicity.

Are modern welding fumes dangerous?

Yes, welding fumes can be harmful if not properly managed. They may contain metals like manganese, which affect the nervous system over time. Always use ventilation, fume extractors, or respirators in enclosed spaces. Many newer machines also reduce spatter and fume output. Safety gear and airflow remain essential on every job.

How long does it take to learn professional welding?

Most professional welding programs take 6 to 18 months to complete. Hands-on practice is key to mastering techniques like stick, MIG, or TIG. Certifications from AWS or other bodies boost job chances. Dedicated learners often land jobs within a year. Like any skilled trade, mastery comes with consistent, real-world experience.

Conclusion

Modern welding blends centuries of craftsmanship with cutting-edge innovation. From smart inverters to AI-assisted robots, the tools keep evolving—but skilled hands still drive quality. Whether you’re restoring a classic car or building a steel frame, precision and reliability matter more than ever.

Ready to start your next welding project with trusted experts? Contact Capitol Iron Works DC today. They deliver top-quality work, on time and built to last—right in your neighborhood.