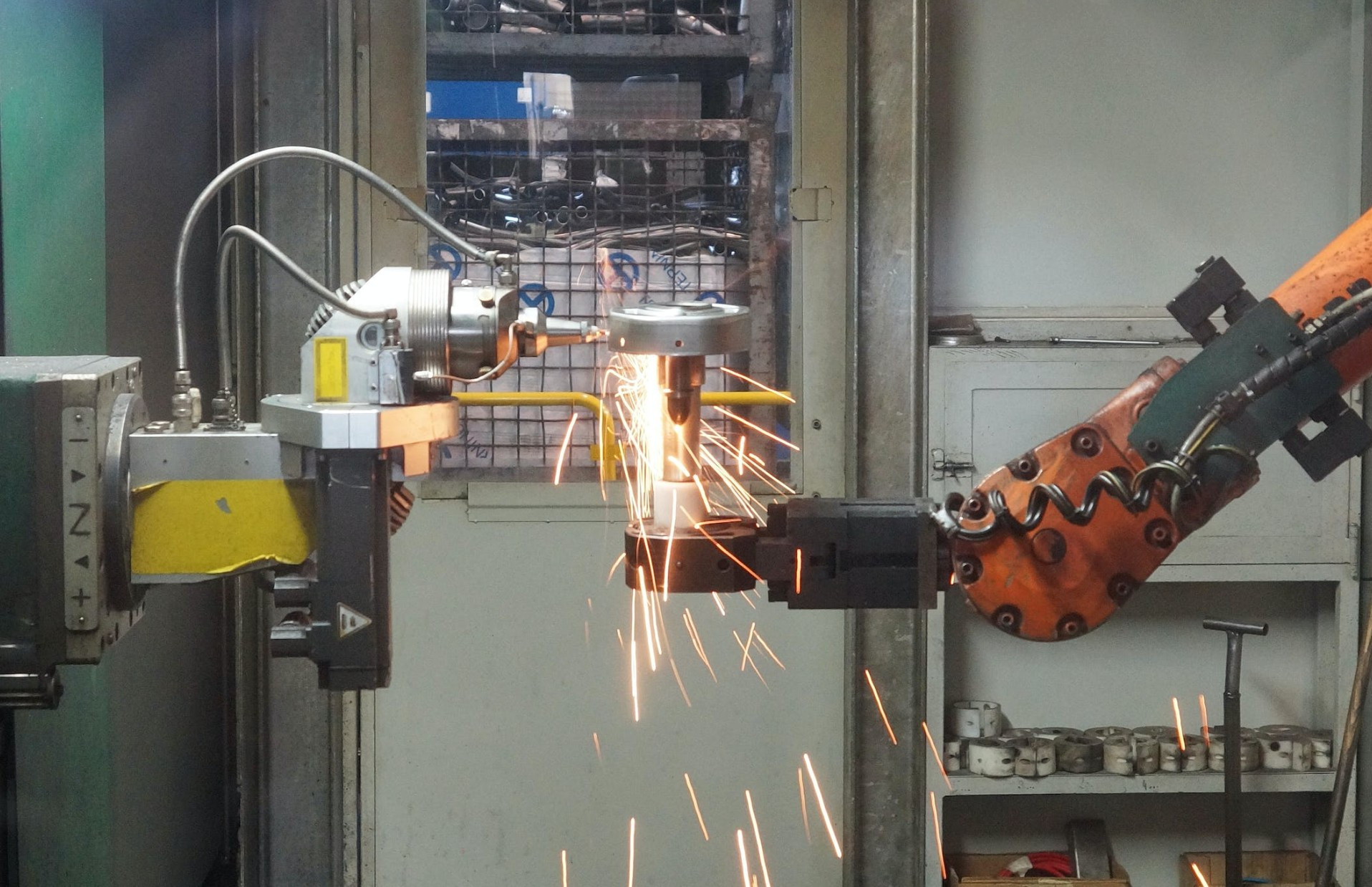

Welding has come a long way since its early days. In the past, welders relied solely on their hands and eyes to join metal parts. Then came machines that could weld faster and more consistently. But these machines were big, dangerous, and hard to use.'

Luckily, nowadays a new type of robot is here to help: the cobot, or collaborative robot. Now, cobots are taking on welding tasks. They're changing how we make cars, planes, and even kitchen appliances. In this article, we'll explore everything about cobot welding. From what it is to how it's making factories smarter and safer, we've got you covered. Let's explore!

What is Cobot Welding?

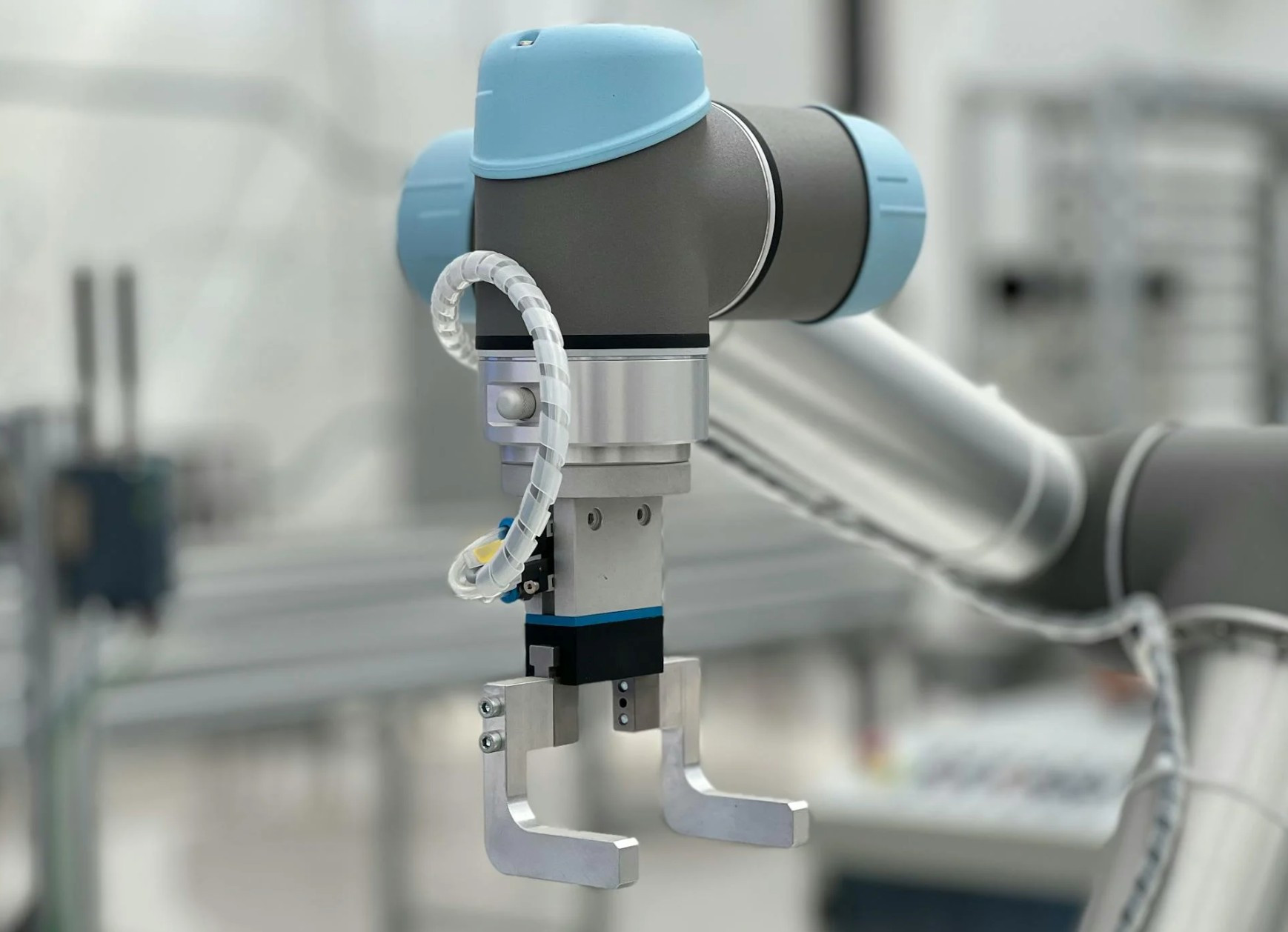

Cobot welding is a new way of joining metal parts using special robots called cobots. "Cobot" is short for "collaborative robot." These robots are different from the big, dangerous welding robots you might see in old factories.

Cobot welding systems typically feature a compact, meticulously controlled mechanical arm equipped with a welding torch. The cobot can be programmed to perform different kind of welding processes like MIG or TIG welding.

What makes cobot welding special is that humans can work right next to the cobot. The cobot has sensors that make it stop if it touches a person. This means no more safety cages. Also, teaching a cobot is easy. You can move the cobot's arm by hand to show it where to weld. Or you can use simple software, like a video game controller.

Benefits of Cobot Welding

1. Safer Workplaces:

Cobot welders are built with safety in mind. They have sensors that make them stop if they touch a person. This means no more dangerous accidents. Workers don't need to hide behind fences. They can work right next to the cobots. This also reduces strain on workers' bodies. No more bending or reaching into awkward spots. Cobot welding follows strict safety rules (like ISO/TS 15066) to keep everyone safe.

2. More Work Done:

Cobots can weld day and night without getting tired. They don't need breaks or holidays. This means they can make more parts in less time. Also, cobots weld the same way every time. This leads to fewer mistakes. Fewer mistakes mean less time fixing errors. And when the cobot is welding, workers can do other important tasks. All this adds up to making more products faster.

3. Easy to Use:

You don't need to be a robot expert to use a cobot welder. Teaching a cobot is simple. You can move its arm by hand to show it where to weld. Or you can use a simple screen, like a big tablet. It's as easy as playing a video game. This means even new workers can set up the cobot quickly. If you need to make a different part, just teach the cobot the new job. It's quick and doesn't need a lot of downtime.

4. Fits Anywhere:

Cobots are small compared to old welding robots. They don't need big safety cages. This means you can put them almost anywhere in your workshop. You can even put them right next to where people are working. This saves a lot of space. In small workshops, this is a big deal. You can have more welding stations in the same space. Or you can use the extra space for other machines or storage.

5. Helps with Worker Shortage:

Finding skilled welders is getting hard. Many welders are retiring, and not enough young people are learning the trade. Cobots help with this problem. They can do a lot of the basic welding. This frees up skilled welders to do the tricky jobs that need a human touch. Also, young people like working with new tech like cobots. It makes welding seem more modern and interesting. This can help attract new talent to the field.

6. Cost-Effective:

Starting a cobot welding setup costs less than getting a big traditional welding robot. You don''t need to buy expensive safety fences or rebuild your workshop. Running costs are lower too. Cobots use less power than big robots. And because they make fewer mistakes, you waste less material. You also save on worker injury costs. All these savings mean you can earn back your cobot investment faster. In business talk, we say cobots offer a quicker "return on investment" or ROI.

What's Included in a Cobot Welding Package?

When you decide to bring cobot welding into your workshop, you're not just buying a robot. You're getting a complete package that has everything you need to start welding smarter and safer. Think of it like getting a new smartphone. It's not just the phone; you also get a charger, earbuds, and apps. A cobot welding package is similar. It has all the parts, programs, and support to get you up and running quickly.

Let's break down what you typically get in a cobot welding package:

A. Hardware Components:

1. Cobot Arm: This is the heart of the package. It''s the robotic arm that does the welding. Cobot arms come in different sizes. Some can lift and weld small parts like in a phone. Others can handle bigger parts like car doors. The "payload capacity" tells you how heavy a part it can work with.

2. Welding Torch and Consumables: The torch is like the cobot's welding pen. It creates the arc that melts the metal. The package also includes things the torch uses up, like tips and nozzles. These are called consumables because you'll need to replace them over time.

3. Wire Feeder and Spool: In MIG welding, you need a wire that melts to join metals. The wire feeder is like a fishing reel. It feeds the wire to the torch at just the right speed. The spool is where the wire is wound up, like thread on a spool.

4. Controller and Teach Pendant: The controller is the cobot's brain. It tells the arm how to move. The teach pendant is like a big, rugged tablet. You use it to program the cobot, just like you use a touchscreen to set up your phone.

B. Software and Programming Tools:

1. Proprietary Cobot Operating Systems: Each cobot brand has its own special software, like how iPhones use iOS. This software makes the cobot run smoothly and safely.

2. Welding-Specific Software Packages: These are extra programs just for welding. They help set things like how hot the weld should be or how fast to feed the wire. It's like having a special app for taking great photos on your phone.

3. Simulation and Offline Programming Tools: Before you weld real parts, you can practice in a computer game-like setup. This lets you test and fix problems without wasting materials. You can also program the cobot on a computer while it's still welding, saving time.

C. Safety Devices:

1. Force/Torque Sensors: These are like the cobot's sense of touch. If it bumps into something (or someone) it shouldn't, it stops. This keeps people safe without needing fences.

2. Vision Systems for Part Recognition: These are the cobot's eyes. Cameras help it see where parts are and if they're in the right spot. This means less time setting up and fewer mistakes.

3. Area Scanners and Light Curtains: These watch the area around the cobot. If someone gets too close while it's welding, the cobot slows down or stops. It's like an invisible safety bubble.

D. Training and Support:

1. On-site or Remote Training Programs: The company doesn't just drop off the cobot. They teach you and your team how to use it. They might come to your workshop or train you over the internet.

2. Technical Support and Maintenance Plans: If something goes wrong or you have questions, there's help. It's like having tech support for your phone. Some plans also include regular check-ups to keep your cobot in top shape.

3. Software Updates and Upgrades: Just like your phone gets new features with updates, so does your cobot. These can make it work better or even do new things.

Cobot Welding vs Traditional Welding

When we talk about welding in factories, there are three main ways to do it: by hand (manual welding), with big industrial robots (traditional robotic welding), or with collaborative robots (cobot welding). Each has its strengths and weaknesses. Let's compare them to see why cobot welding is becoming a game-changer.

First, let's look at manual welding. This is where a skilled welder uses a torch or electrode to join metals. The big plus here is flexibility. A good welder can adjust on the fly for tricky welds or unique parts. They're great for custom jobs, repairs, or when you only need a few parts. But there are downsides. Welding is tough on the body. The American Welding Society reports that 75% of welders experience some work-related pain or injury. Also, weld quality depends on the welder's skill and how they're feeling that day. Tired welders make more mistakes.

Now, let's talk about traditional robotic welding. These are those big, caged robots you might see in a car factory. They're fast and consistent. A study by the International Federation of Robotics found that robotic welding can be up to five times faster than manual welding. These robots don't get tired, so quality stays high. They're perfect for high-volume jobs, like welding thousands of car frames. But they have drawbacks too. They're expensive to set up. You need the robot, safety fencing, and a specialized programmer. A basic setup can cost over $100,000. They're also not flexible. Changing their task is complex and time-consuming. This makes them less ideal for small batches or varied products.

Now let's talk about cobot welding, the new kid on the block. Cobots are designed to work alongside humans, not locked away. They have built-in safety features like force sensors that make them stop if they touch someone. This means no need for big safety cages. A study in the Journal of Manufacturing Systems found that eliminating safety barriers can reduce a work cell's footprint by up to 50%. Cobots are also easy to use. Many can be programmed by simply moving their arm to teach the weld path. This ease of use is a big deal. Cobots are also perfect for medium-volume jobs or products that change often.

So, when do you use each type? Manual welding still wins for one-off custom jobs or repairs. Traditional robots are best for high-volume, never-changing tasks like in big auto plants. But cobot welding fills a huge middle ground. They're for medium-volume jobs, varied products, or when humans and robots need to work together.

Role of Cobot Welding in Industry 4.0

Industry 4.0 is all about making factories smart. It's where machines talk to each other, and data helps make better decisions. In this world, cobot welding isn't just about joining metals. It's a key player in the connected, data-driven factory.

Cobots are like IoT (Internet of Things) devices. They collect data while they weld. Things like how hot the weld is, how fast the wire feeds, or if there are any defects. This data goes into the factory's central systems. It might be a MES (Manufacturing Execution System) that manages production, or an ERP (Enterprise Resource Planning) system that handles everything from orders to shipping. With this data, managers can spot trends. Maybe one cobot is using more wire than others. That could mean it needs maintenance. Or they might see that morning welds have fewer defects. So, they adjust schedules for better quality.

But it doesn't stop there. Cobot welding systems are starting to use AI (Artificial Intelligence) and machine learning. These smart programs can look at weld data and learn. For example, they might notice that certain settings work better for thicker metals. Then, they automatically adjust the cobot for the best weld. Some systems can even predict when a cobot will need repairs. In Industry 4.0, cobot welding isn't just about the weld. It's about being a smart, connected part of the entire manufacturing process.

Cobot Welding Applications

Automotive Industry

Cobot welders are changing how we make cars. They're great for welding car body parts, like doors and fenders. These parts need consistent welds to fit together perfectly. In one case, a major U.S. automaker used cobots to weld seat frames. They reported a 20% increase in throughput and a 3% improvement in weld quality. Cobots also help make electric cars. They weld battery packs that need to be watertight and strong. As electric car sales grow (BloombergNEF predicts 54% of global car sales will be electric by 2040), cobot welding will be crucial.

Aerospace Manufacturing

Airplanes need perfect welds. A single bad weld could be catastrophic. Cobots are up to this high-stakes task. They weld parts for plane bodies and wings. These welds must be strong but also light. Every extra pound means more fuel used. Cobots also help in airplane maintenance. They can do precise repair welds on engine parts.

Heavy Machinery and Construction

Think of the big yellow machines on construction sites. Cobots help make these. They weld parts like excavator buckets and bulldozer frames. These welds need to withstand huge forces. Many major equipment makers use cobots to weld hydraulic cylinders. They chose cobots because they could easily move them between different welding stations. This flexibility is key in making different types of machinery.

Metal Fabrication and Job Shops

These are workshops that make all sorts of metal products. One day it's custom gates, the next it's HVAC ducts. Cobots shine here because they're easy to reprogram for different jobs. Fabricators could take on more varied jobs without hiring more welders.

Consumer Goods and Appliances

Cobots help make things we use every day. They weld parts for refrigerators, ensuring the cooling system doesn't leak. They also make fun stuff like bicycles. A European bike maker uses cobots to weld frames. They say cobots let them make custom bikes faster. It's a win for both the shop and bike lovers who get their dream rides quicker.

Emerging Applications

Cobot welding is finding new uses all the time. In shipbuilding, they're welding parts of ship hulls. These welds must withstand saltwater and storms. In railways, cobots are welding tracks. There's even a role in 3D printing. As metal 3D printing grows, cobots are there to weld support structures or finish printed parts.

Cost-Benefit Analysis of Cobot Welding

When a factory owner thinks about getting cobot welding, the first question is often, "Is it worth the money? Investing in Cobots is a big decision for any factory. The upfront cost can seem daunting, but when you dig into the numbers, it often turns out to be a smart financial move. Let"'s break down the costs and benefits to see why more and more factories are turning to cobots.'

First, let's talk money. A basic cobot welding setup might cost you around $40,000, but a more advanced one can run up to $100,000 or more. This price tag covers a lot: the cobot arm that does the welding, the controller that's like its brain, and the software that tells it what to do. Then there's the welding gear itself – the torch, wire feeder, and power supply. Don't forget about fixtures to hold your parts in place. It all adds up. But here's the thing: compared to traditional welding robots that can cost over $100,000 just for the basics, cobots are a bargain.

Now, the payoff. Cobots are like tireless workers. They don't need lunch breaks or weekends off. They can boost productivity by 40% to 70%. That's like having two workers for the price of one! Quality goes up too. Cobots weld the same way every time. The defects can drop by 90% after getting cobots. Less fixing mistakes means saving on materials and time. Safety is another big win. Cobots have sensors to avoid accidents. With fewer injuries, you save on medical bills and insurance.

But it's not all upfront savings. You've got ongoing costs like training your team to work with cobots, regular maintenance (about 3% of the cobot's price yearly), and maybe upgrades down the line. Even so, many businesses find that cobots pay for themselves fast. Why? Because all those productivity and quality gains add up quickly. In today's fast-paced markets, getting products out faster and with fewer defects is gold.

FAQs About Welding Cobots

A. Are cobot welders safe to work alongside without barriers?

Yes, cobot welders are designed for safe collaboration. They have sensors that detect contact and stop or slow down to avoid harm. They follow strict safety standards like ISO/TS 15066. However, safety measures like light curtains are still used for high-risk tasks. In most cases, you can work right next to a cobot without fences, making workspaces more efficient.

B. Can cobots handle the same welding tasks as skilled human welders?

Cobots excel at repetitive, precise tasks. They can match or exceed humans in consistency and speed for these jobs. But human welders still win for complex, varied welds or repair work. The best setup is often a team: cobots handle routine welds, freeing skilled welders for the tricky stuff. It's a win-win.

C. How long does it take to program a cobot for a new welding job?

Not long at all. Many cobots use "teach by demonstration." You just move the cobot"'s arm to show the weld path. It''s like teaching a kid to draw. Most simple jobs take 15-30 minutes to program. More complex tasks might take a few hours. Compare that to days for traditional robots. This quick setup is why cobots are great for small batches.'

D. Can cobot welders work in harsh or hazardous environments?

Most cobots are built tough. They can handle heat, dust, and vibration common in welding shops. Some are even rated for harsh conditions like shipyards. But very extreme environments (think underwater or in extreme heat) might need special models or protection. Always check the cobot's specs. For most welding tasks, standard cobots are plenty rugged.

E. What kind of maintenance do cobot welding systems require?

Cobots are low-maintenance compared to traditional robots. They need regular checks, like cars need oil changes. This usually means a yearly service, costing about 3% of the cobot's price. You'll also replace welding consumables like tips and nozzles. But overall, downtime is minimal. Many cobots even self-diagnose issues, so problems get fixed fast.

F. Can existing welding fixtures and jigs be used with cobots?

Usually, yes. Cobots are designed to fit into existing setups. If your fixtures hold parts steady for human welders, they'll likely work for cobots too. You might need small tweaks for cobot reach or clearance. But the goal is minimal disruption. This compatibility is a big money-saver. You're not starting from scratch.

G. How does cobot welding impact job roles and skills in manufacturing?

Cobots change roles, not eliminate them. Welders become cobot operators, a higher-skill job. They program cobots, oversee quality, and handle complex welds. It's like moving from manual typing to managing a word processor. Some worry about job loss, but often, cobot efficiency lets companies grow and hire more. Training is key. Many cobot makers offer programs to upskill workers.

H. Are there any limitations to the types of materials cobots can weld?

Cobots can weld most common metals: steel, aluminum, stainless steel. They handle thin sheets to thick plates. But very exotic materials or tricky alloys might still need human touch. Also, cobots have payload limits. A small cobot can't weld huge, heavy parts. But for most jobs in automotive, aerospace, or general fabrication, cobots have you covered.

Takeaway

In this article, we've seen how cobot welding is changing the game. It's not just a new tool; it's a whole new way of working. Cobots make welding safer, faster, and more precise. They fit into small shops and big factories alike. But here's the best part: cobots aren't replacing welders. They're teaming up with them. It's like having a tireless, super-precise helper. Cobots handle the repetitive stuff, so welders can focus on the tricky, creative work. This teamwork is the future. As factories get smarter with Industry 4.0, this human-cobot partnership will be key. Cobots bring the data and consistency; humans bring the expertise and problem-solving.

So, if you're in manufacturing, it's time to take a good look at cobot welding. Whether you're a small shop fighting to compete or a big factory looking to get leaner, cobots can give you an edge. They're not just a fad. They're a ticket to being faster, safer, and more flexible.