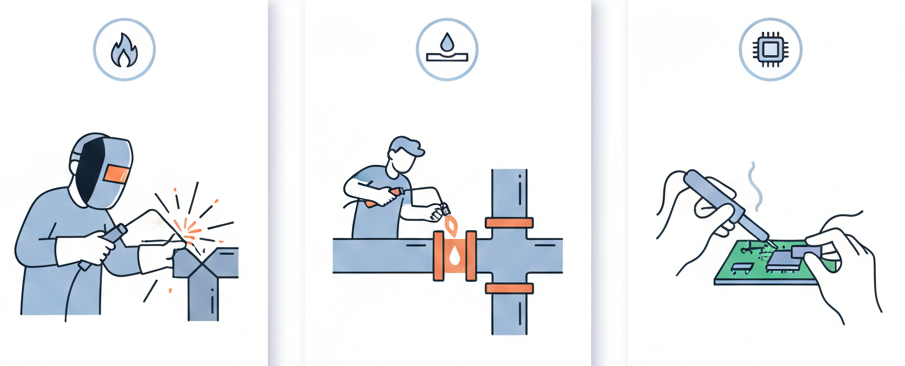

Welding, brazing, and soldering are the three primary methods for joining metal pieces together. Each technique plays a different role across industries like manufacturing, electronics, construction, and repair work. Understanding which method to use is critical for creating durable joints that actually last.

These differences matter because choosing the wrong process can lead to weak connections or failed projects. Manufacturing plants depend on knowing heat levels and strength requirements. Electronics manufacturers need precise, delicate joints without damaging components. This article walks you through everything: heat temperatures, how filler materials work, joint strength, required tools, and real-world applications.

What Welding, Brazing, and Soldering Actually Are?

Welding

Welding uses extreme heat to melt base metals together at the joint. The metal pieces actually fuse into one solid material, becoming as strong as the original metal itself. This process typically requires temperatures above 1,500°F (800°C), sometimes reaching 3,000°F or higher. Welding creates the strongest permanent bonds possible between metals. It's the go-to choice for heavy-duty applications in construction, shipbuilding, and automotive manufacturing. Common methods include MIG, TIG, and stick welding. Because of its high heat, welding works best on thicker metals and larger structures.

Brazing

Brazing sits between welding and soldering in terms of heat requirements and strength. It melts filler material (called braze) between metal pieces without melting the base metals themselves. Temperatures typically range from 1,100°F to 1,600°F (600–870°C), creating a very strong permanent bond. The filler metal flows into the joint space through capillary action, bonding everything together smoothly. Brazing works excellently on various metals, including steel, copper, and aluminum. This method is popular in HVAC systems, refrigeration units, and jewelry making. It provides superior strength compared to soldering while requiring less extreme heat than welding.

Soldering

Soldering uses the lowest temperatures of these three joining methods, typically between 350°F and 700°F. Solder is a metal alloy that melts and flows into the joint without melting base metals. This delicate process creates reliable bonds perfect for electronics, circuit boards, and precision work. The joint strength is weaker than welding or brazing, but perfect for components that don't experience heavy stress. Soldering is quick, affordable, and doesn't damage sensitive electronic parts with excessive heat. Plumbers use it for copper pipes, electricians use it for wiring, and manufacturers use it everywhere. It's the method of choice when precision and protection matter most.

Key Differences Between Welding, Brazing & Soldering

Temperature Levels & Heat Impact

Welding operates at extremely high temperatures, typically exceeding 1,500°F and often reaching 3,000°F. These intense heat levels actually melt the base metals together completely. The metals fuse into one unified structure at the molecular level. Brazing works at more moderate temperatures, ranging from 1,100°F to 1,600°F. This mid-range heat melts the filler material but leaves base metals solid. Soldering uses the gentlest approach with temperatures between 350°F and 700°F only.

The temperature choice directly impacts what materials you can join together successfully. Soldering protects heat-sensitive components like circuit boards and delicate electronics. Welding's extreme heat means it works best on thick, robust metal structures. Brazing offers a balanced middle ground for joining various metal types without damage. Understanding heat levels helps you choose the right process for each specific project and material combination.

Joint Strength & Durability

Welding creates the strongest possible joints because base metals literally fuse. The resulting bond equals or exceeds the original metal's structural integrity. These connections withstand extreme stress, vibration, and heavy loads indefinitely. Brazing produces medium-strength joints that are still quite durable and reliable. The braze filler creates a metallurgical bond stronger than solder alone. Soldered joints offer the weakest connections of the three methods available.

However, joint strength must match your actual application requirements, not just preference. Heavy structures like bridges absolutely demand welding's superior strength characteristics. HVAC systems need brazing's balanced strength without excessive heat damage. Electronics and delicate components perform perfectly with soldering's lighter connections. Choosing the wrong method leads to premature failure and potential safety hazards everywhere. Match your process to real-world stress levels your finished product will experience.

Filler Metals & Metallurgical Behavior

Welding doesn't truly use filler material in the traditional sense here. The base metals themselves melt and combine into one continuous structure. This fusion process creates joints as strong as the original material composition. Brazing relies on filler metal that melts and flows through capillary action. The filler material bonds to both base metals without melting them. This creates a strong, sealed joint that bridges the gap between parts.

Soldering uses solder alloy filler that melts and wets the joint surfaces. The wetting process means solder flows and adheres to both metal pieces. This creates reliable electrical and mechanical bonds for precise applications. Different filler metals work best for different projects and base metal combinations. Brazing fillers suit structural applications, while soldering fillers excel in electronics. Understanding how filler metals behave helps you select the perfect joining method correctly.

Equipment & Skill Requirements

Welding requires specialized machines like MIG, TIG, or stick welders. Welders need shielding gas, torches, safety equipment, and extensive training. The learning curve is steep because technique greatly impacts joint quality. Brazing equipment includes torches, induction heating units, or specialized brazing stations. Operators need training on temperature control and proper filler metal handling. The skill requirement sits between welding and soldering in complexity overall.

Soldering demands simpler equipment like irons, stations, or hot air tools. Even beginners can produce acceptable joints with basic soldering training quickly. Soldering equipment costs far less than welding or brazing machines. However, professional soldering still requires proper technique for reliability and safety. Each method has different learning curves and equipment investment requirements. Your budget and available training often determine which process works best initially.

Safety, Costs & Usability

Welding poses the highest safety risks due to extreme heat and light. Welders face burns, eye damage, and harmful fume exposure regularly. Proper ventilation, protective gear, and training are absolutely essential always. Brazing involves moderate safety concerns with medium temperatures and fume production. Operators need respiratory protection and fire-safe work environments for protection. Soldering is generally the safest process with lowest heat and fumes.

Equipment costs vary dramatically across these three joining methods significantly. Welding machines cost thousands of dollars initially for basic setups. Brazing equipment ranges from moderate to expensive depending on automation. Soldering irons and stations cost far less, making soldering very accessible. Operational costs also differ based on materials, energy, and maintenance needs. Soldering typically offers the lowest total cost for small projects. Welding provides best value for large structural work despite higher costs.

When to Use Welding, Brazing, or Soldering?

Use Welding When

Welding becomes the clear choice when structural integrity and maximum strength matter. Bridges, building frames, and load-bearing steel structures absolutely require welding's strength. Heavy equipment, vehicles, and machinery depend on welding for safety everywhere. Pipeline construction, shipbuilding, and aerospace manufacturing all rely on welding exclusively. These industries cannot accept weaker joints because lives literally depend on it. The permanent, incredibly strong fusion welding provides simply cannot be matched elsewhere.

Welding also works best when joining thick metals that require deep penetration. Thin materials weld poorly because the base metal melts too quickly. Welding excels when you need speed for high-volume production environments. The process creates joints faster than brazing for many metal combinations. Consider welding when your budget allows for equipment investment and operator training. Structural steel connections, automotive frames, and industrial fabrication demand welding consistently.

When cost per joint doesn't matter as much as absolute reliability, welding wins. Critical infrastructure projects cannot afford joint failures under any circumstances whatsoever. Emergency repairs on vehicles often require welding for reliable strength restoration. Choose welding whenever the consequences of joint failure would be catastrophic. Your finished product's safety and durability requirements should drive this decision ultimately.

Use Brazing When

Brazing shines when you need to join dissimilar metals together successfully. Copper to steel, aluminum to brass, and mixed compositions all braze beautifully. Soldering struggles with these combinations because wetting becomes problematic. Welding damages some metals through excessive heat, making brazing ideal. The medium heat preserves material properties while creating excellent bonds. HVAC systems, refrigeration units, and plumbing applications benefit greatly from brazing.

Brazing produces exceptionally clean, accurate joints without visible distortion or warping. Metal art, jewelry, and precision instruments demand this clean appearance consistently. Cookware, musical instruments, and decorative items showcase brazing's aesthetic advantages beautifully. The process creates smooth, professional-looking connections that look intentional and beautiful. Brazing also works well for joining different metals without galvanic corrosion concerns. The filler metal bridges dissimilar materials while maintaining structural integrity throughout.

Consider brazing when you need strength without melting base metals into one mass. The joint remains clearly visible, which appeals to craftspeople and artists. Brazing allows rework and repair more easily than welding can. Heat-sensitive components near joints survive brazing better than welding heat. Choose brazing for custom fabrication, artistic metalwork, and precision assembly work. Industrial applications like automotive radiators and heat exchangers depend on brazing.

Use Soldering When

Soldering becomes essential whenever electronics and precision circuitry are involved. Circuit boards, PCBs, and electronic components require soldering's gentle heat. Excessive heat would damage transistors, capacitors, resistors, and other sensitive components. Soldering protects delicate semiconductor connections while establishing reliable electrical paths. The low temperature environment preserves component functionality and extends equipment lifespan significantly. Professional electronics manufacturing and repair work relies almost entirely on soldering.

Soldering works perfectly for plumbing applications joining copper pipes together reliably. Electrical wiring, plumbing fixtures, and HVAC piping all benefit from soldering. The process creates leak-proof connections suitable for water and gas lines. Soldering equipment is affordable and portable, making it practical for field work. Plumbers and electricians choose soldering because it's quick and economical. The low cost per joint makes soldering attractive for budget-conscious projects everywhere.

Choose soldering when precision, speed, and affordability matter most to you. Hobby projects, small repairs, and electronics prototyping all favor soldering strongly. The learning curve is gentle, making it accessible to beginners quickly. Soldering requires minimal safety precautions compared to welding's demanding requirements. For delicate components, sensitive materials, and small-scale work, soldering is unbeatable. Professional manufacturers and experienced technicians recognize soldering's unique advantages for specific applications.

Frequently Asked Questions

Q1: Can you braze steel and copper together successfully?

Yes, brazing actually works excellently for joining dissimilar metals like steel and copper. The brazing filler material bonds to both metals without melting them. This is one of brazing's biggest advantages over welding. Welding would damage copper through excessive heat exposure. Brazing creates strong, reliable joints between different metal types consistently.

Q2: Is soldering safe for beginners to learn and practice?

Absolutely, soldering is one of the safest metal joining methods available. The low temperatures and equipment pose minimal risk to beginners. Safety hazards are far less severe compared to welding or brazing. Proper ventilation and basic hand protection keep beginners safe effectively. Many hobbyists learn soldering without formal training or professional supervision needed.

Q3: Why do welded joints cost more than soldered or brazed joints?

Welding requires expensive equipment, specialized training, and professional certification from operators. The machines themselves cost thousands of dollars for basic setups. Brazing and soldering use cheaper equipment that costs significantly less upfront. Welding also consumes more energy per joint compared to other methods. Complex structures demand more welding time, increasing labor costs substantially overall.

Q4: Can you weld aluminum safely, or is it too difficult?

Welding aluminum is definitely possible but requires specialized techniques and equipment. TIG welding works best for aluminum because it offers precise control. Aluminum needs different filler materials and shielding gas than steel. The process demands more skill and experience than welding plain steel. Professional welders recommend aluminum welding for experienced operators only, not beginners.

Q5: What's the difference between lead-free and lead-based solder?

Lead-free solder is safer and complies with modern environmental regulations today. Lead-based solder historically worked well but posed serious health hazards. Lead-free solder has higher melting points, requiring hotter irons slightly. Both types create reliable electrical connections when used with proper technique. Most manufacturers now use lead-free solder exclusively for safety reasons.

Q6: How long do welded, brazed, and soldered joints typically last?

Welded joints last indefinitely if properly executed and maintained regularly. The fused metal bond doesn't weaken significantly over normal time. Brazed joints are also extremely durable, lasting decades without degradation. Soldered joints can last many years but weaken under extreme stress. Environmental factors and usage intensity affect lifespan across all three methods.

Q7: Can you braze cast iron, or does it crack easily?

Brazing cast iron is actually possible but requires careful temperature control. Cast iron is prone to thermal shock and cracking during heating. Slow heating and cooling prevents dangerous cracks from developing in material. Pre-heating the entire workpiece reduces stress significantly throughout the brazing process. Professional brazing on cast iron demands experience to avoid expensive material waste.

Q8: Which joining method works best for stainless steel applications?

Welding is the preferred method for most stainless steel applications. TIG welding produces the cleanest welds and best corrosion resistance. Brazing also works well for stainless steel without damaging material properties. Soldering isn't recommended for structural stainless steel due to weak joints. Choose based on your specific application requirements and strength demands involved.

Conclusion

Welding, brazing, and soldering each serve distinct purposes in manufacturing and repair. Choose your method based on three critical factors: required joint strength, temperature limits, and specific application needs. Consider whether components need extreme durability, dissimilar metal joining, or heat-sensitive protection.

If you're seeking professional metal fabrication services, Capitol Iron Works DC delivers exceptional expertise and quality craftsmanship. Contact Capitol Iron Works DC today to discuss your fabrication needs with professionals who understand these joining methods thoroughly.