Welding is a skilled trade that offers solid career opportunities across America. Many people think learning to weld requires years of expensive education. In fact, you can get certified in just a few months at specialized schools. These programs teach you practical skills that employers actually need in the field.

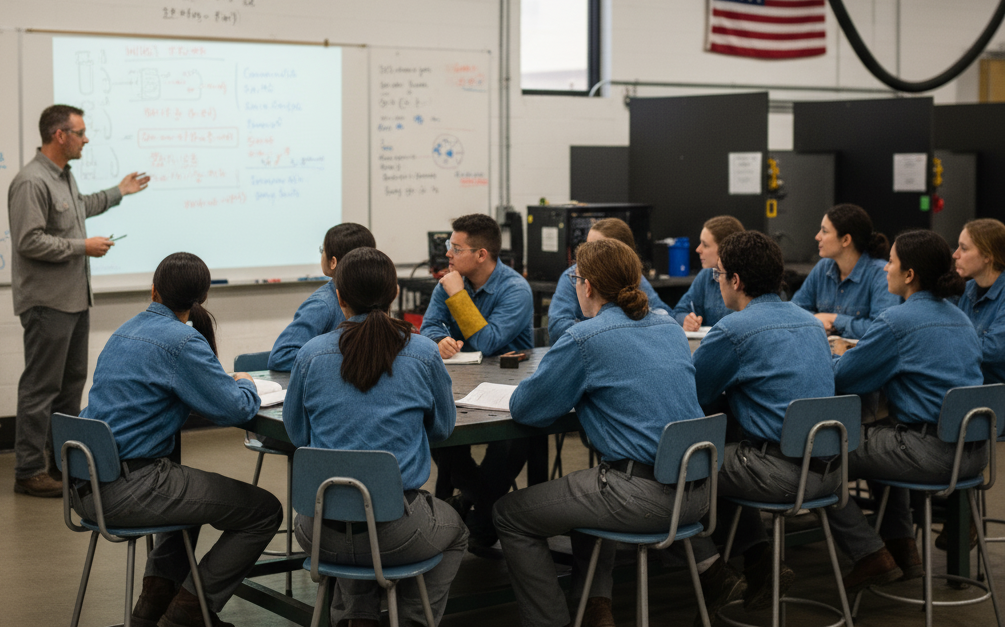

Welding schools provide hands-on training with real equipment and experienced instructors. Students learn different techniques like MIG, TIG, and stick welding through daily practice. Most programs also cover safety protocols, which are clearly essential in this profession. According to industry experts, certified welders can earn competitive wages right after graduation.

This guide will help you discover the best welding schools nationwide. We'll explore programs that go the extra mile to prepare students for success. Let's dive into the top institutions where you can start your welding career.

Top Welding Schools in America

1. Tulsa Welding School

Tulsa Welding School is believed to be among the oldest welding institutions nationwide. The school operates multiple campuses across states like Texas, Oklahoma, and Florida. Students can choose from various programs that typically last seven months or less. Many people think their hands-on training approach really makes a difference in learning. The curriculum covers MIG, TIG, stick welding, and pipe welding techniques comprehensively. Instructors bring real-world experience from the field, which clearly benefits student learning. Job placement assistance is offered to graduates seeking employment after certification. According to industry experts, their completion rates remain impressively high year after year. Financial aid options are available for those who qualify for assistance. The school has built strong relationships with employers looking for skilled welders. Interestingly, many graduates find work within weeks of finishing their programs. Tulsa Welding School definitely stands out for its reputation and proven track record.

2. Lincoln Electric Welding School

Lincoln Electric Welding School operates from Cleveland, Ohio, with an outstanding industry reputation. The company itself manufactures welding equipment, so students learn on top-quality machines. Programs range from basic welding courses to advanced specialized certification training options. Research suggests their instructors are among the most experienced in the field. Students get access to state-of-the-art facilities that mirror real-world working conditions. The school offers both short-term and extended programs to fit different schedules. Many graduates go on to work for major manufacturing and construction companies. Financial aid and veterans' benefits are available for eligible students seeking support. From my point of view, learning at a manufacturer's school provides unique advantages. The connection to industry gives students an edge when job hunting begins. Employers often prefer candidates trained on Lincoln equipment specifically. Without a doubt, this school prepares welders for demanding professional careers effectively.

3. Hobart Institute of Welding Technology

Hobart Institute is located in Troy, Ohio, and focuses entirely on welding education. The school has been training welders for over fifty years with dedication. They offer everything from beginner courses to advanced pipe and structural welding. Students can earn AWS certifications that are recognized widely across the industry. Instructors gave it their all to ensure every student masters essential techniques. The hands-on training approach means students spend most time actually welding daily. Classes are kept small, which allows for personalized attention and better learning. According to experts, Hobart graduates are highly sought after by top employers nationwide. The school also provides welding inspector and educator certification programs for advancement. Since the facility uses modern equipment, students learn current industry standard practices. Many people think the focused curriculum really accelerates skill development significantly. For example, their pipe welding program is considered one of the best available.

4. AWS Welding School (American Welding Society)

AWS operates welding schools and partners with institutions across the United States. The American Welding Society sets industry standards, so their training carries weight. Students can pursue AWS certifications that employers trust and actively seek out. Programs cover various welding processes including underwater and robotic welding techniques comprehensively. Research suggests that AWS-certified welders often command higher salaries in the market. The curriculum is regularly updated to reflect the latest technologies and methods. Instructors must meet strict qualifications set by the society's educational standards. Financial assistance programs help many students afford quality welding education and training. From an industry perspective, AWS certification is like a gold standard credential. Graduates find opportunities in aerospace, automotive, construction, and maritime industries easily. The society also offers continuing education for welders wanting to expand expertise. Clearly, AWS-affiliated schools provide credentials that open doors throughout your welding career.

5. Midwest Technical Institute

Midwest Technical Institute operates campuses in Illinois, offering comprehensive welding training programs. Students can complete their certification in as little as seven months typically. The school provides job placement support, which led to impressive graduate employment rates. Many instructors worked as professional welders before transitioning into teaching full-time roles. Programs include MIG, TIG, stick, and flux-cored arc welding techniques thoroughly. Hands-on training makes up the majority of class time each day. According to program reviews, students appreciate the practical, no-nonsense approach to education. Financial aid options are available for those who meet the requirements. The school maintains relationships with local and regional employers seeking skilled workers. Interestingly, some students land apprenticeships even before completing their full program. Class sizes remain manageable, ensuring everyone gets adequate attention from instructors daily. Without a doubt, Midwest Technical Institute prepares students for real-world welding careers.

6. Williamson College of the Trades

Williamson College is located near Philadelphia and offers a unique tuition-free program. Students graduate with an associate degree and valuable welding certifications after three years. The school is exclusively for young men, providing housing and meals included. Many people think this approach removes financial barriers to quality education completely. Students learn multiple trades including welding, masonry, carpentry, and machine tool technology. The welding curriculum covers both structural and pipe welding extensively and thoroughly. Since classes combine academics with hands-on training, graduates are well-rounded professionals. Research suggests employers highly value the work ethic Williamson graduates consistently demonstrate. Job placement rates remain extremely high, with many students receiving offers early. From a financial perspective, graduating debt-free gives students a tremendous career advantage. Instructors go the extra mile to ensure students master every technique required. As many know, this college provides life-changing opportunities for dedicated young people.

7. Pennsylvania College of Technology

Penn College is located in Williamsport and offers degree programs in welding technology. Students can earn associate or bachelor's degrees depending on their career goals. The welding program is accredited and recognized by industry professionals nationwide widely. According to college statistics, their graduates enjoy strong employment rates after finishing programs. The curriculum includes advanced welding processes, metallurgy, blueprint reading, and quality control. Hands-on labs feature modern equipment that students will encounter in professional settings. Instructors bring both teaching credentials and extensive industry experience to classrooms daily. Financial aid, scholarships, and work-study programs help students manage educational costs effectively. Many graduates work for aerospace, energy, manufacturing, and construction companies successfully. The degree option provides a pathway to supervisory and engineering positions eventually. From my point of view, combining technical skills with academic knowledge increases opportunities. In fact, employers often prefer candidates with both certifications and formal degrees.

8. Advanced Welding Institute (formerly Rosedale Technical College)

Advanced Welding Institute operates in Pittsburgh, Pennsylvania, with a strong local reputation. Programs typically last six to nine months, allowing for quick career entry. Students learn stick, MIG, TIG, and flux-cored welding in well-equipped facilities. The school emphasizes practical skills that employers in the region actively seek. Many graduates find work in construction, manufacturing, and pipeline industries relatively quickly. According to industry feedback, their hands-on approach produces job-ready welders consistently. Instructors have worked in the field and understand what employers expect. Financial aid options are available for students who qualify for assistance programs. Class sizes are intentionally kept small to maximize individual attention and learning. The school maintains partnerships with local companies looking for skilled welding professionals. Interestingly, some students receive job offers before even completing their certification programs. Without a doubt, Advanced Welding Institute provides focused training for practical career success.

9. The Refrigeration School (RSI)

RSI is based in Phoenix, Arizona, and offers welding alongside HVAC programs. The welding program can be completed in as few as seven months. Students learn essential techniques including TIG welding, which is crucial for HVAC work. Many people think combining welding with refrigeration skills increases employment opportunities significantly. The curriculum covers pipe welding, blueprint reading, and safety practices comprehensively. Instructors are experienced professionals who understand both welding and HVAC industries well. Job placement assistance helps graduates connect with employers in Arizona and beyond. According to program outcomes, many students find work shortly after earning certifications. The Phoenix location offers year-round comfortable weather for outdoor welding practice sessions. Financial aid and veterans' benefits are available for those who meet criteria. From a career perspective, having multiple skills makes you more valuable generally. For example, HVAC technicians with welding skills can handle more complex repairs.

10. Tulsa Welding School – Jacksonville Campus

The Jacksonville, Florida campus offers the same quality training as other locations. Students can complete programs in approximately seven months with intensive hands-on practice. The school covers MIG, TIG, stick, and pipe welding techniques thoroughly. Florida's strong construction and maritime industries provide excellent job opportunities for graduates. Research suggests that welders in Florida often find work in shipbuilding easily. Instructors bring years of practical experience from various welding fields professionally. The school provides job placement services, connecting students with employers actively hiring. Financial aid options help many students afford their welding education and training. According to graduate feedback, the supportive learning environment really makes a difference. Class sizes allow for personalized instruction and plenty of practice time daily. Many employers in the region specifically recruit from Tulsa Welding School campuses. Without a doubt, this Jacksonville location prepares students for successful welding careers.

How to Choose the Right Welding School?

Choosing the right welding school requires careful consideration of several important factors. First, you should check if the school offers accreditation and industry-recognized certifications. Accredited programs ensure you receive quality education that employers will actually respect. According to experts, AWS certifications are particularly valuable in the welding industry. You'll also want to research the school's job placement rates and connections. Schools with strong employer relationships often help graduates find work faster after completion. The location matters too, since some regions have more welding opportunities available. Think about whether you prefer a quick certificate program or a degree.

Program length and cost are practical considerations that definitely impact your decision. Some schools offer programs as short as six months for fast entry. Others provide associate or bachelor's degrees that take longer but offer advancement. Many people think shorter programs work well if you need income quickly. However, degree programs may lead to supervisory positions and higher pay eventually. Financial aid availability should influence your choice, especially if funding is tight. Research suggests comparing total costs including tuition, materials, and living expenses helps. Don't forget to ask about payment plans or scholarships available.

The hands-on training quality really makes a difference in how well you learn. Visit campuses if possible to see facilities and equipment students actually use. Modern equipment exposure ensures you're learning on machines employers use currently today. Class sizes matter because smaller groups mean more personalized attention from instructors. Instructors with real-world experience bring valuable insights that textbooks simply cannot provide. Ask about the student-to-teacher ratio and lab time available during programs. From my point of view, more practice time leads to better skill development.

Finally, consider the school's reputation within the welding industry and local community. Talk to current students or graduates about their experiences and career outcomes. Employers' opinions matter, so ask companies which schools they prefer recruiting from. Online reviews can provide helpful insights, but verify information through multiple sources. Since this is a major investment, take time to research thoroughly. Interestingly, many successful welders say choosing the right school launched their careers. Make a decision that aligns with your goals, budget, and timeline perfectly.

Career Outlook After Welding School

1. Construction Welding Careers

Construction welding offers steady work opportunities across residential and commercial building projects. Many welders find employment with general contractors building bridges, skyscrapers, and infrastructure. The work often involves structural steel welding, which requires precision and attention. According to industry reports, construction welders can earn competitive wages with benefits. Travel opportunities exist since major projects happen in different cities and states. Some welders prefer staying local while others enjoy traveling to new locations.

Research suggests construction demand remains strong as infrastructure continues aging and needs repair. Experienced welders may advance to foreman or supervisor positions overseeing entire teams. From my point of view, construction welding provides variety since every project differs. Weather conditions can affect outdoor work schedules during certain seasons though. Without a doubt, this field offers excellent opportunities for dedicated professionals.

2. Manufacturing and Industrial Welding

Manufacturing facilities need welders for producing vehicles, machinery, equipment, and consumer goods. These positions typically offer stable employment with regular hours and good benefits. Many people think factory work provides more predictability than construction project-based jobs. Welders might specialize in automotive, aerospace, shipbuilding, or heavy equipment manufacturing. The work environment is usually indoors, protected from weather conditions outside. According to experts, manufacturing welders often receive comprehensive training on specialized processes.

Career advancement opportunities include quality control, inspection, and production management roles eventually. Some facilities offer tuition reimbursement for welders pursuing additional certifications or degrees. Interestingly, robotic welding technology creates demand for welders who program and maintain equipment. Since manufacturing evolves constantly, welders must stay updated on new techniques. For example, electric vehicle production requires different welding skills than traditional cars.

3. Pipeline and Energy Sector Welding

Pipeline welders work on oil, gas, and water pipeline construction and maintenance. This field often pays premium wages, especially for welders willing to travel. Many pipeline projects occur in remote locations requiring temporary relocation for workers. According to industry data, experienced pipeline welders can earn substantial incomes annually. The work demands high skill levels since pipeline integrity is absolutely critical. Welders must pass rigorous certification tests specific to pipeline welding standards.

Energy sector opportunities extend beyond pipelines to power plants and renewable installations. Wind turbine construction and solar facility development need skilled welders increasingly nowadays. From a career perspective, energy work provides excellent long-term stability and growth. However, the work can be physically demanding in challenging environmental conditions. As many know, pipeline welders who go the extra mile earn respect.

4. Underwater and Specialized Welding

Underwater welding combines commercial diving with welding skills for unique high-paying opportunities. These specialists work on ships, offshore oil platforms, dams, and bridges. The job requires both welding certification and commercial diving credentials for safety. Research suggests underwater welders can earn six-figure salaries with sufficient experience. However, the work involves significant risks and demands extensive specialized training first. Only a small percentage of welders pursue this challenging career path.

Other specialized welding includes aerospace, nuclear facilities, and precision instrument manufacturing sectors. These fields require advanced certifications and often security clearances for employment. According to industry feedback, specialized welders enjoy job security and premium compensation. The positions demand perfection since mistakes can have serious consequences obviously. Clearly, specialized welding careers reward those willing to invest in advanced training.

5. Welding Inspection and Quality Control

Welding inspectors ensure work meets codes, standards, and safety requirements on projects. This career path suits experienced welders wanting less physically demanding work eventually. Inspectors need AWS Certified Welding Inspector credentials, which require passing rigorous examinations. Many people think inspection work offers excellent pay without the physical strain. The role involves examining welds, reviewing blueprints, and documenting quality control processes. According to salary data, certified inspectors often earn more than traditional welders.

Career advancement can lead to quality manager or safety director positions. Some inspectors work as independent consultants serving multiple companies and earning premium rates. From my point of view, inspection combines technical knowledge with problem-solving skills effectively. The work requires attention to detail and strong communication abilities daily. Without a doubt, this path provides excellent opportunities for seasoned welding professionals.

Conclusion

Welding schools provide the foundation for rewarding careers in essential industries nationwide. Quality training programs equip students with certifications that employers actively seek and value. The right school makes a significant difference in your job prospects. Graduates with solid skills and recognized credentials find opportunities faster and earn better.

Choosing an accredited welding school is an investment in your future success. Research your options carefully, considering location, cost, program length, and job placement support. Many welders build stable, well-paying careers that support families and provide satisfaction. Take the first step today toward a skilled trade career. Your future in welding starts with finding the best educational fit.